Crusher Rebuilding

Precision Repair and Superior Longevity

We provide comprehensive repair and manufacturing services for high-wear crusher components, meeting critical demands in the mining, power generation, and quarrying industries. With expert capabilities in complete welding, machining, turning, and both O.D. & I.D. grinding for large diameters, we restore your crusher parts to OEM specifications, ensuring they meet or surpass original performance standards.

Boron Hardening Process

Martin Equipment’s exclusive Boron Diffusion Hardening Process offers next-level protection for your critical wear parts. Developed initially for NASA’s Apollo Space Module, this proprietary technology is not a coating or traditional heat treatment. Instead, boron diffusion integrates with the part’s material at an intermetallic level, significantly enhancing resistance to wear, corrosion, abrasion, and impact.

Benefits of Boron Diffusion:

- Guaranteed 2-Day Emergency Service: Our Priority One Emergency Service ensures critical parts are ready when you need them most.

- Extensive Wear Protection: Increased resistance to cavitation, corrosion, abrasion, erosion, and impact.

- Long-Term Partnerships: Our innovation and quality have built trust with our clients and suppliers, ensuring long-term satisfaction and reliability.

Types of Crushers We Service

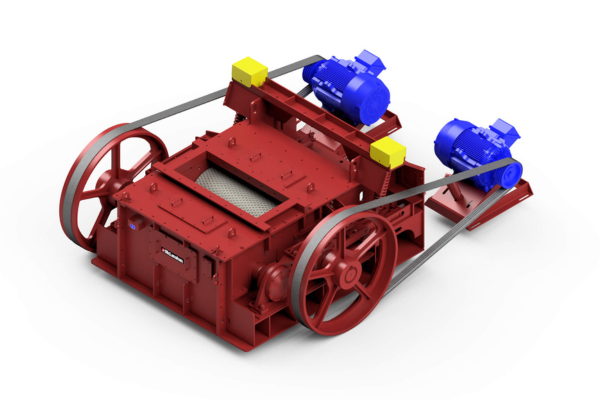

Roll Crushers

- Roll Assembly

- Housing

- Main Frame

- Cheek plates

- Drive system

Jaw Crushers

- Pitman Jaws

- Swing Jaws

- Eccentric Shafts

- Fly wheel

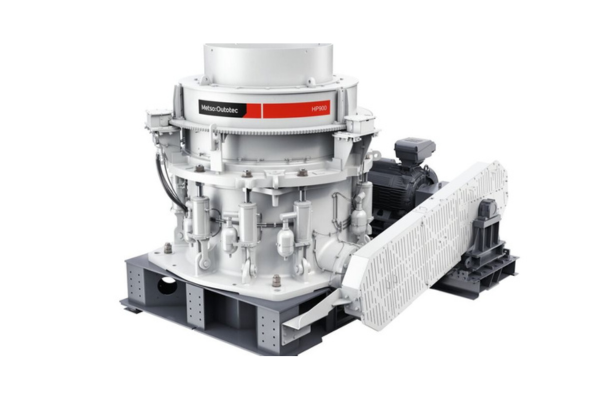

Cone Crushers

- Main Frames

- Head Assemblies

- Bowls

- Adjustment Rings

- Countershaft Assemblies

- Eccentric Assemblies

- Tramp Release Systems